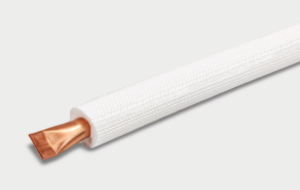

PE isolerade kopparrör

Kopparrör för installation i kall- och varmvatten samt värmesystem. Isolerat kopparrör med mantel av vit lågdensitet-polyeten och metermärkning. isolerat m ed Cu-Dhp 99,9% kopparrör ett expanderat polyetenrör, sluten cell och en extern LDPE-folie.

Maximal brandsäkerhet med självsläckande DIN 4102-B1, SBI BL S1D0. Resistent mot yttre kemiska ämnen och ultravioletta strålar.

| PE-INSULATED COPPER TUBE PRODUCT CATEGORIES | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Diameter (inch) | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 7/8 | |

| Flowtech SPLIT | 0.7 mm | 0.7 mm | 0.7 mm | 0.8 mm | |||

| flowtech POLAR | 0.75 mm | 0.75 | 0.75 mm | 0.9 mm | 0.9 mm | ||

| flowtech MAXI | 0.8 mm | 0.8 mm | 0.8 mm | 1.0 mm | 1.0 mm | 1.12 mm | |

| flowtech PLUS | 1.0 mm | 1.0 mm | 1.0mm | 1.0 mm | 1.0 mm | 1.12 mm | |

| White PE Insulated Copper Tube | |||||||

|---|---|---|---|---|---|---|---|

| Sustainability | Fully recyclable | ||||||

| Specificities | Unique aesthetical appearance Excellent mechanical strength | ||||||

| Fire | Excellent flame extingushing properties SBI BL S1 DO | ||||||

| Health | Produced without (H) CFC Complies to REACH Complies to VOC (Volatile organic componental ) Complies to RoHS (Restriction of Hazardous Substances) | ||||||

| Certificates | Complies to the German EnEV CE system 3 certified | ||||||

| Service temperatures | Wide service temperature range Minimum -80 °C Maksimum 95 °C (EN 14707) | ||||||

| Additional information | Standart Thickness: 6,9,13,19 | ||||||

| Water | Closed cell structure for good water vapor barrier Water vapor resistance μ ≥ 5000 (EN13469) Water absorption WS05 (EN 13472) | ||||||

| Insulation | Semi-flexible thermoplastic foam Excellent insulation properties Lambda 0.040 W/mK at 40 °C (EN ISO 8497) Lambda 0.036 W/mK at 0 °C (EN ISO 8497) | ||||||

| White PE Insulated Copper Tube | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Diameter (inch) | 1/4 | 3/8 | 1/2 | 1/2 | 5/8 | 3/4 | 7/8 |

| Pipe Thickness (mm) | 0,8 | 0,8 | 0,8 | 0,9 | 1 | 1 | 1,12 |

| Insulation Thickness (mm) | 6-9-13-19 | 6-9-13-19 | 6-9-13-19 | 6-9-13-19 | 6-9-13-19 | 6-9-13-19 | 6-9-13-19 |

| Operation Pressure (bar) | 134 | 89 | 72 | 84 | 62 | 52 | 42 |

| Coil Length (meter) | 15/50 | 15/50 | 15/50 | 15/50 | 15/50 | 15/50 | 15/50 |

| TECHNICAL SPECS OF COPPER PIPE | |||||||

|---|---|---|---|---|---|---|---|

| Chemical Composition | 99,9% Cu-Dhp | ||||||

| Conformity | EN 12735 – 1 | ||||||

| Unit Breaking Load | Min. R=220n/mm2 | ||||||

| Elongation A% | A% min=45% | ||||||

| Physical Condition | Annealed | ||||||

| Internal Surface | Glossy, pertectly clean conforming ASTM B-280 and EN12735-1 legislation | ||||||

| Heat Conduction at 20°C | 364W/mK | ||||||

| Condition | Sealed ends, dehumified | ||||||